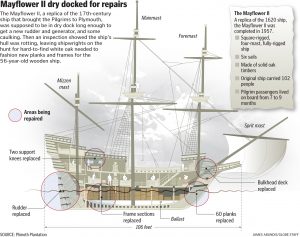

Wharf boring beetles, (Narcerdes melanura) have invaded the wood of the Mayflower II, according to an article in the Boston Herald, and much of the Plymouth-based ship’s hull suffers from rot. The popular tourist attraction, considered to be the star of the show at Plimoth Plantation, needs about 60 percent of the its planking replaced below the waterline, and was becoming unsafe for visitors.

According to Whit Perry, director of maritime preservation and operations at Plimoth Plantation: “She needs major structural frame repairs and planking. Without a project of this magnitude now, her days would be numbered — and that would be tragic,” for the replica built in Great Britain and sailed to the U.S. as a gift of friendship in 1957. In November 2016 the ship sailed to Mystic Seaport for a 7.5 million dollar refit estimated to take 2.5 years for completion.

One of the major problems in repairing replica ships is where to find the needed lumber? Repairs need to be made with white oak “air dried” for over three years, a commodity almost impossible to locate in large quantities in our modern age. Fortunately for the folks at Plimoth Plantation they were able to find a good stand of oak trees in Kentucky sufficient for their needs.

When the Sea Lion ship was sent to Scarano Boat Builders in Albany New York for repairs we had no idea just how hard 300 year old oak lumber was to come by. Scarano Boat Builders has earned an excellent reputation for building and restoring replica sailing ships of all sizes. However, several weeks ago we got a call from Albany saying they hadn’t been able to locate the lumber needed for the replacement deck beams and Sampson Posts for the Sea Lion. Nowadays, laminated timbers are often used for support beams due to the lack of availability of seasoned white oak.

But the Sea Lion was designed and built just like English ships were constructed 400 years ago long before laminated beams were first used in the mid nineteenth century. We offered to search for sources of white oak and after contacting lumber companies all across the east coast could find nothing in the needed size and quantity for the job other than green or reclaimed lumber.

Since green wood was not an option we explored the possibility of using reclaimed lumber and discovered it came with many drawbacks along with its high cost just as well. Reclaimed wood often shows signs of decades of use, contains mold and mildew, and is infected with termites and other wood-eating pests. Reclaimed wood often contains old nails, metal pegs, or even bullets, all hazardous objects when hit with a power saw.

Not willing to throw in the towel, I remembered a Virginia company renowned for building beautiful timber frame homes and commercial buildings. Several years earlier, Dreaming Creek, located nearby in Powhatan Virginia, had helped our militia group by providing the wood needed for two cannons we were building. Dreaming Creek built the The Blackfriars Playhouse in historic Staunton, Virginia, the world’s only re-creation of Shakespeare’s indoor theatre and the Marine Corps Semper Fidelis Memorial Chapel just to name two of their many accomplishments.

After searching through all their mills, Stuart Bailey, my contact at Dreaming Creek, was able to locate the needed lumber. Stuart gave Ron Blackburn, Sea Lion Foundation board member and master carpenter, and me a tour of his Powhatan plant where we were able to see the quality of the white oak we would be getting. The Sea Lion Foundation owes Stuart Bailey, and everyone at Dreaming Creek, a huge thanks for all their hard work in locating the lumber. The wood is already being cut to the sizes needed by Scarano Boat Builders and prepared for shipment to Albany.

Just as the Mayflower II has become loved by visitors to Plimoth Plantation we feel certain the Sea Lion will soon become the center of attention at Henricus Historical Park. While the journey is far from over, locating the proper lumber for the restoration project has moved us one giant-step closer to our goal.

– Dennis Strawderman, Founder of the Henricus Citie Militia.